Tips to Operate Portable Crusher in Winter

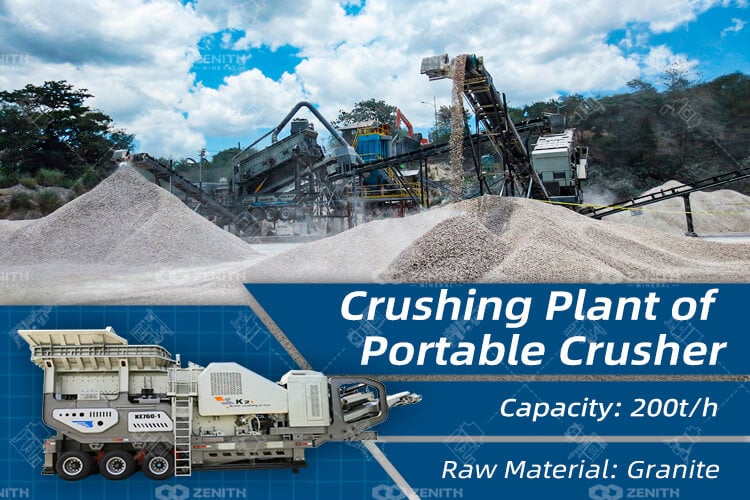

Operating a portable crusher plant during the winter months poses unique challenges due to the cold weather conditions. However, with proper planning and precautions, it is possible to maintain efficient and uninterrupted crushing operations. This article aims to provide a comprehensive guide with valuable tips to help operators successfully run a portable crusher plant in winter.

1. Equipment Preparation

Before the onset of winter, it is crucial to conduct thorough equipment preparation to ensure optimal performance and prevent potential issues. Consider the following steps:

- Inspect and lubricate all moving parts: Cold temperatures can cause metal components to contract, leading to increased friction and wear. Proper lubrication of bearings, belts, and other moving parts is essential to reduce strain and enhance equipment longevity.

- Check electrical systems: Freezing temperatures can affect electrical connections and components. Inspect wiring, connections, and control panels for any signs of damage or corrosion. Ensure proper insulation and protection against moisture to prevent malfunctions.

- Verify fluid levels: Cold weather can impact fluid viscosity, potentially affecting the performance of hydraulic systems, lubrication, and coolant. Check and maintain appropriate fluid levels as recommended by the equipment manufacturer.

- Test safety devices: Ensure that all safety devices, such as emergency stops and warning alarms, are in proper working condition. Test and verify their functionality to guarantee the safety of operators and equipment.

2. Cold-Weather Considerations

Operating a portable crusher plant in winter requires addressing specific cold-weather considerations to mitigate potential problems. Implement the following measures:

- Adequate heating: Maintain a warm environment in control rooms and operator cabins to enhance operator comfort and prevent equipment freezing. Consider installing additional heating equipment, such as space heaters or insulation, if necessary.

- Fuel management: Cold temperatures can affect the performance of fuel, leading to issues with combustion and engine operation. Use winter-grade fuel and ensure proper fuel storage in insulated tanks to prevent fuel gelling or freezing.

- Conveyor belt maintenance: Cold weather can cause conveyor belts to become stiff and brittle, increasing the risk of damage. Regularly inspect belts for signs of wear, tension, or misalignment. Keep them clean and properly lubricated to ensure smooth operation.

- Snow and ice removal: Develop a snow and ice removal plan to keep access roads, platforms, and equipment clear. Regularly remove snow and ice buildup from conveyor belts, chutes, and other critical areas to prevent blockages and ensure uninterrupted material flow.

3. Operator Training and Safety:

Proper training and safety protocols are essential for winter operations. Consider the following aspects:

- Equipment operation training: Ensure operators are trained in the specific challenges and precautions associated with operating portable crusher plants in winter. Provide comprehensive training on equipment controls, emergency procedures, and safe operating practices.

- Personal protective equipment (PPE): Provide appropriate winter PPE, including insulated gloves, boots, and clothing, to protect operators from cold temperatures and potential hazards. Emphasize the importance of wearing and properly using PPE at all times.

- Slip and fall prevention: Implement measures to prevent slips and falls, such as anti-slip surfaces, handrails, and clear signage. Regularly remove snow and ice from walkways and work areas, and use non-corrosive de-icing agents to ensure a safe working environment.

- Emergency preparedness: Establish clear protocols for emergency situations, such as equipment failures, power outages, or extreme weather events. Train operators on emergency procedures, including evacuation plans and communication protocols.

Operating a portable crusher plant in winter requires careful planning, equipment preparation, and adherence to safety protocols. By following the tips outlined in this article, operators can successfully navigate the challenges posed by cold weather conditions and maintain efficient crushing operations. Remember, proper equipment maintenance, cold-weather considerations, operator training, and safety are key to ensuring smooth and productive winter operations.